If you can think it,

we can make it.

Customer-specific fiber duct constructions on request.

Mix ‘n’ match all features

HFiberDUCT® comes in a variety of types, including mono ducts and multi duct configurations, which can be customized with or without ribs. They are also available in LSZH (Low Smoke Zero Halogen) material and thick walled for DB (Direct Burial), thin walled for DI (Direct Installation) Or even dobbelt sheated to prevent sharper stones or others – maybe do you need it to be UV proved aswell?

Jacket and pipes are available in the 12 standard colours or transparent (except in case of recycled material), with or without stripes – stripes exactly according to your wishes and design and personal text black or white according to your wish but always accompanied by our brand.

Available with internal grooves and a special surface treatment designed to decrease friction and maximize blowing lengths hence reducing expensive digging costs

Available in either virgin, 100% recycled or re-granulate. Please note that the 12 colours are available for virgin and re-granulate. But in case of recycled material the colours will be dark/brownish

Dimensions customized inner and outer dimensions

Virgin, re-granulate or recycled – it is your call

it makes no difference to the product performance

Environmental considerations are always relevant. Even more so when use of materials have little to no impact on performance.

HFiberDUCT® is available in 100% recycled material.

In many cases there are no reasons for producing virgin plastic, only to bury it in the ground. It is obvious in the case of our cover plates, where aesthetics do not play a big role, as long as the plates are highly visible and strong.

If the product can fully serve its purpose, why not use recycled materials?

Our recommendations are to use the product best suited for the task, while still caring for the environment.

HFiberDuct is available as either virgin, 100% recycled, or re-granulated plastic. Please note that the 12 colors are available for both virgin and re-granulated options. However, for recycled materials, the colors will be darker or brownish.

The performance will remain consistent, and all ducts have been tested.

Information on the material:

Virgin/primary plastic is a plastic filtered from petroleum; the original plastic is milky white, slightly clear. This plastic is filtered out most impurities, completely different substances. 99.99% is pure plastic, just like 9999 gold. It has a strong and uniform quality for every purpose.

Regranulated:

Same properties as virgin. PE regranulates are regranulates made of polyethylene. Within the group of polyethylenes, a distinction is made between other types of plastic. One of these is LDPE, also known as PE-LD. LD stands for low-density and describes the lower density of the material, which is also noticeable in the high light transmission up to complete transparency.

By using PE regranulates, you make your products from 100% recycled polyethylene. This means that you can produce sustainably with high-quality PE regranulate without compromising on your quality standards.

100% recycled plastic is a type of plastic that is recycled many times. Including recycling from plastic bottles, jars and cups. Recycled plastic is recycled from virgin plastic, virgin plastic products. Either recycled from recycled plastic or recycled from itself repeatedly. Good choice for the jacket. Colouring is not an obtion as the 100% recycled material becomes black or brownish.

Customized delivery option

We understand the importance of flexibility and efficiency in the delivery of our products. That's why we offer customized delivery options for our ductds designed to simplify and streamline your project.

In line with our commitment to sustainability, we provide reusable drums, which can be returned and used multiple times. This solution not only reduces waste but also contributes to a cost-effective process, provided they are handled with care and if it makes sense in terms of transportation.

Alternatively, we also offer delivery of ducts in coils, which may be the ideal solution depending on the nature of the project and specific requirements.

Our goal is to meet your needs in the most sustainable and/or cost-effective way possible. Therefore, the choice of delivery method is customized in collaboration with you, based on the specific requirements of your work, who performs it, and how it should be done – all while keeping our shared objective of facilitating workflows, making installations faster and better, and of course, minimizing our environmental footprint.

By focusing on TCO sustainability, we ensure that our solutions serve your interests, our business, and the environment.

This was just a little inspiration; we look forward to working with you to find the optimal solution that suits your needs.

With HFiberDUCT®, quality control is key.

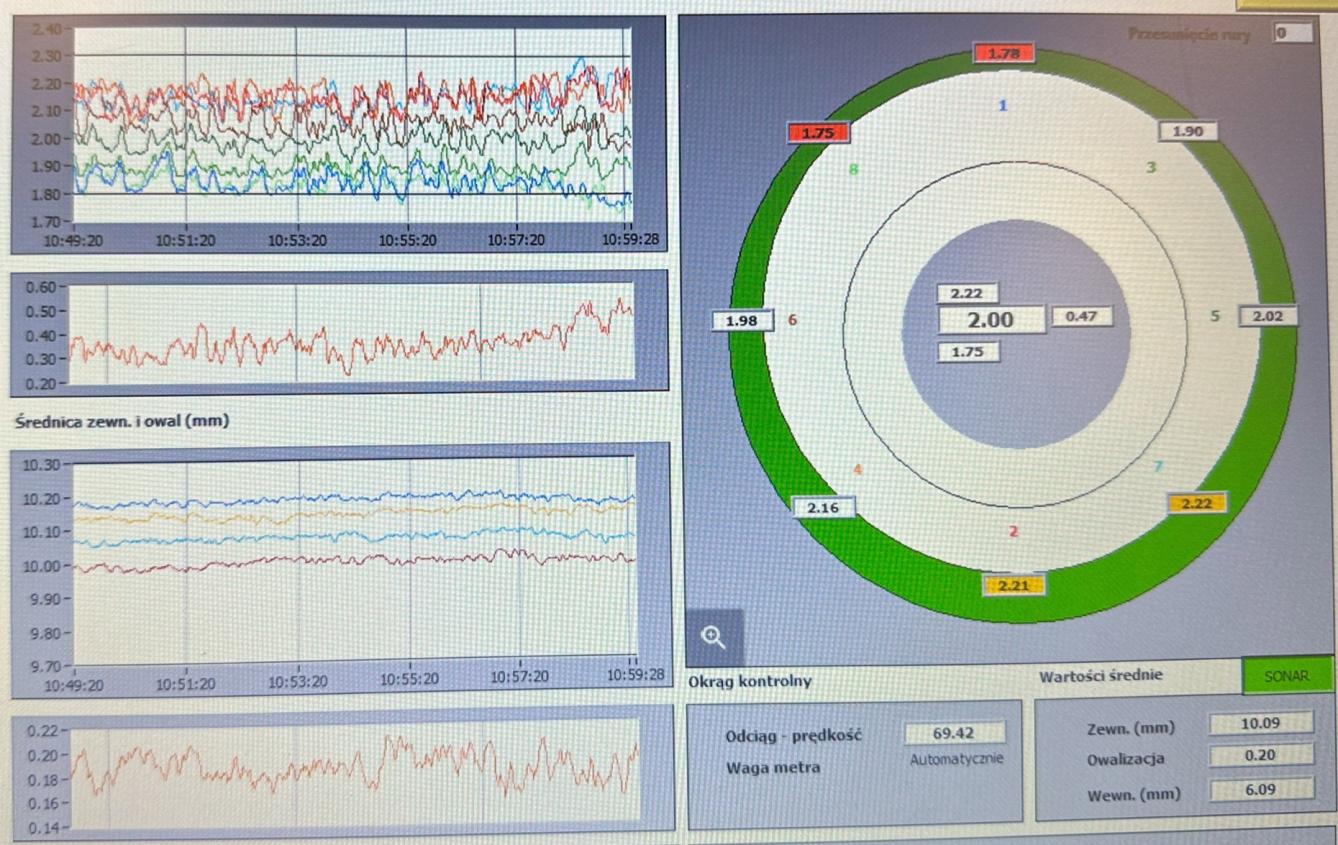

Upon extrusion every single meter of duct is traced, and pressure tested as well as tested for ovality. We are able to track up to every single meter in every single batch of duct.

Quality and traceability are your guarantee of a great product without defects, tested to meet all industry standards.

Chose HFiberDUCT® and avoid expensive installation delays.

Tests:

8 measurements inside and 8 measurements outside are taken to determine if it meets the inner diameter requirements and to check for ovality, ensuring it complies with ovality standards. For the batches we have on the metered pipe, we store the data in their database for traceability purposes. When on the spools, a ball is passed through to check for any constrictions, with a pressure of 20 bar applied afterward to assess its integrity. This process is carried out for all spools. It is crucial to emphasize that it must meet all the above-mentioned requirements for reusability

LET´S TALK - HFiberDUCT®